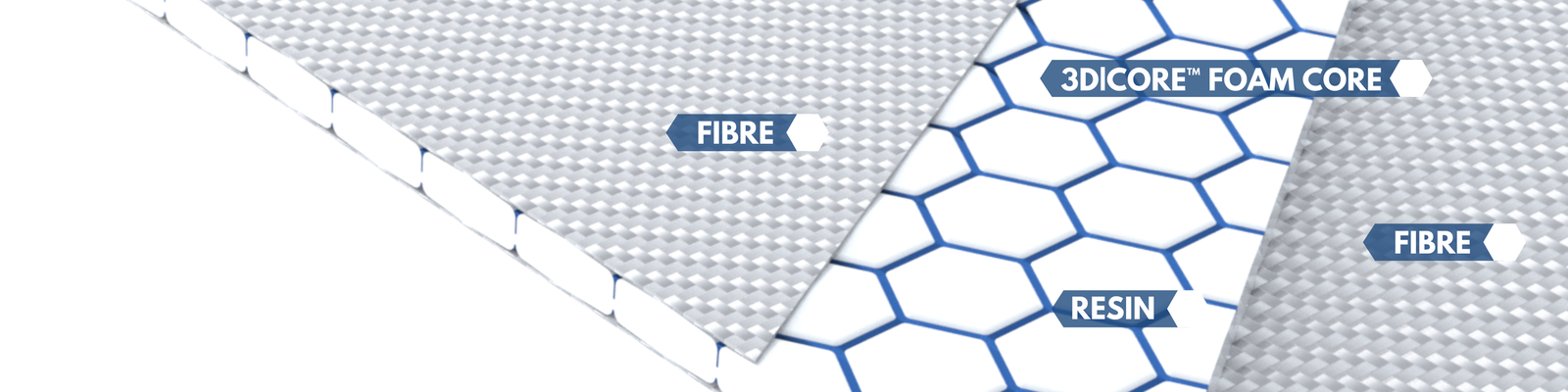

3D|CORE™: The Core for Innovative Sandwich Composites

We offer a selection of structure-reinforcing 3D|CORE™ foam cores, specially developed for the production of sandwich composites. We are pleased to process also special foams like PEI for aviation applications for you.

Advantages of 3D|CORE™

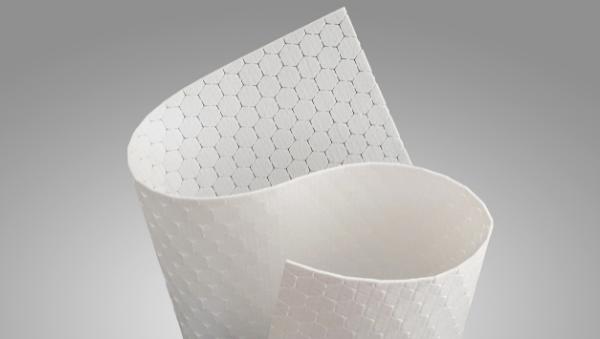

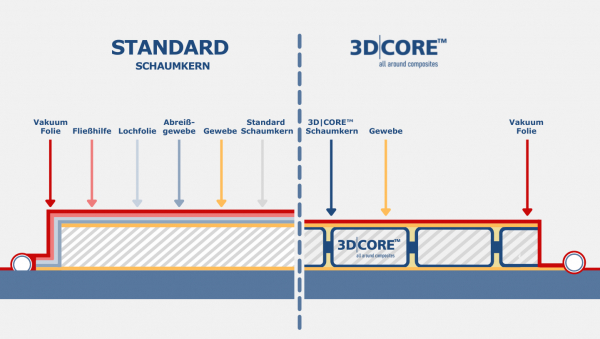

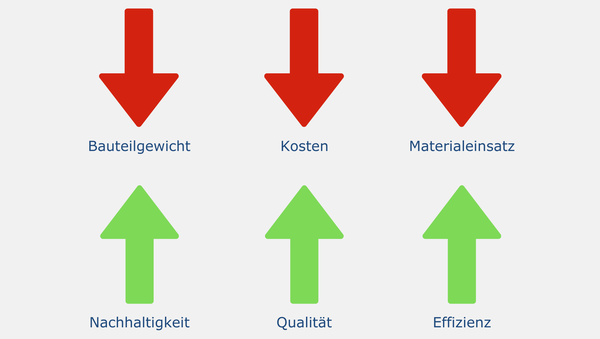

Our 3D|CORE™ foam cores are 3D-formable and ensure optimal resin flow during the manufacturing process. They are the top choice for designers and engineers looking to increase stiffness in a sandwich construction while simultaneously reducing weight. With 3D|CORE™, you achieve superior performance for your composite components.

3D|CORE™ PET FR

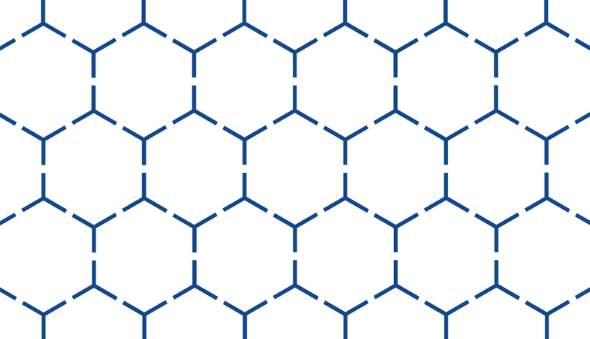

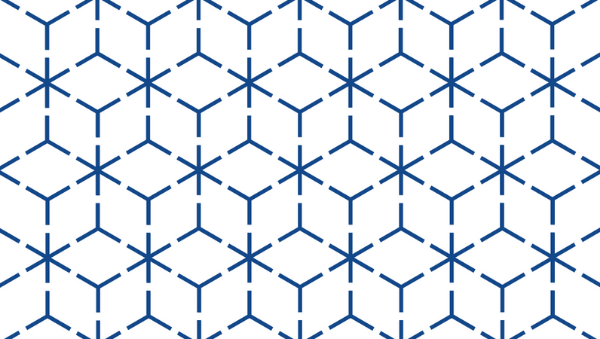

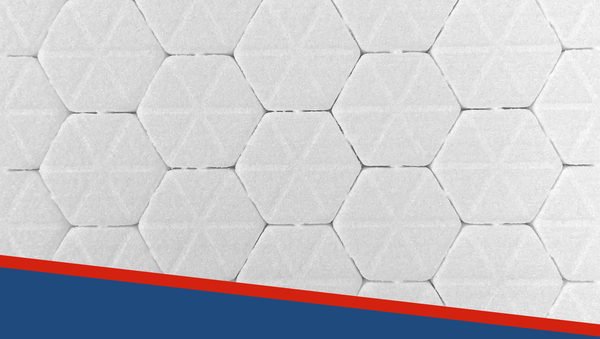

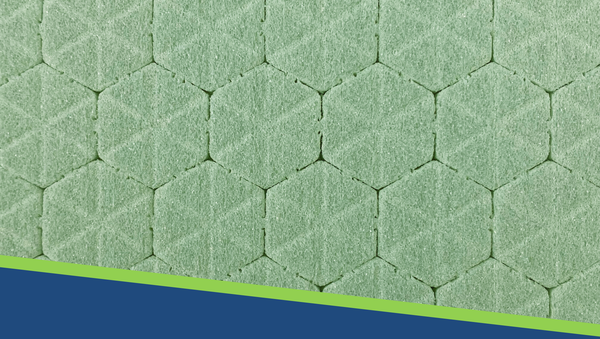

3D|CORE™ PET FR is a closed-cell, thermoplastic, and recyclable rigid foam with excellent FST properties (Flame, Smoke, Toxicity). Its integrated honeycomb structure offers increased flexibility and simplifies handling during production.

3D|CORE™ PET GR

The 3D|CORE™ PET GR foam core is a green foam produced from post-consumer plastics.

This core is a closed-cell, thermoplastic, and recyclable rigid foam with outstanding technical properties.

3D|CORE™ XPS

The 3D|CORE™ XPS foam core is a high-performance polystyrene foam suitable for ultra-lightweight construction applications. Its integrated honeycomb structure offers increased flexibility and simplifies handling during production.

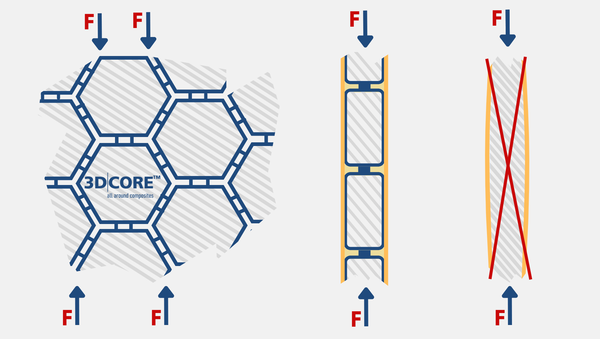

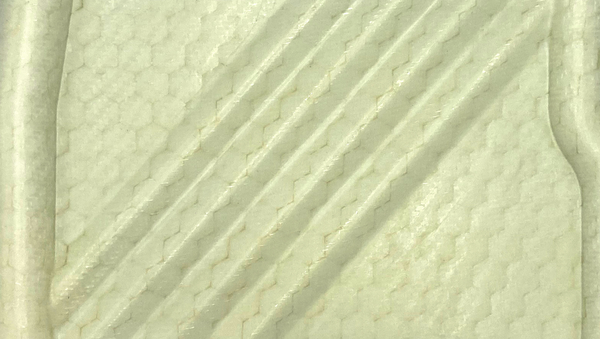

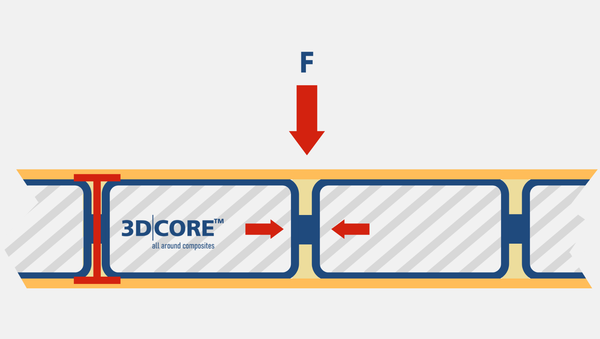

3D|CORE™ is a patented honeycomb structure within a closed-cell polymer foam core. It serves as the foundation for innovative composite materials. The continuous, connected honeycombs provide high deformability, and the enclosed cavities act as a flow aid when filled with synthetic resin. After curing, a dimensionally stable fiber-foam core composite with excellent technical properties is formed. The face sheets are mechanically interlocked by the honeycombs. This prevents delamination and sudden component failure.