fix’n place™ PRODUCTION KITS: Efficient Manufacturing Made Easy

fix’n place™ offers optimized, custom-made quick-build kits for efficient, economical, and sustainable production. The flexibility of 3D|CORE™ is key to fewer, large-format segments, which saves production time.

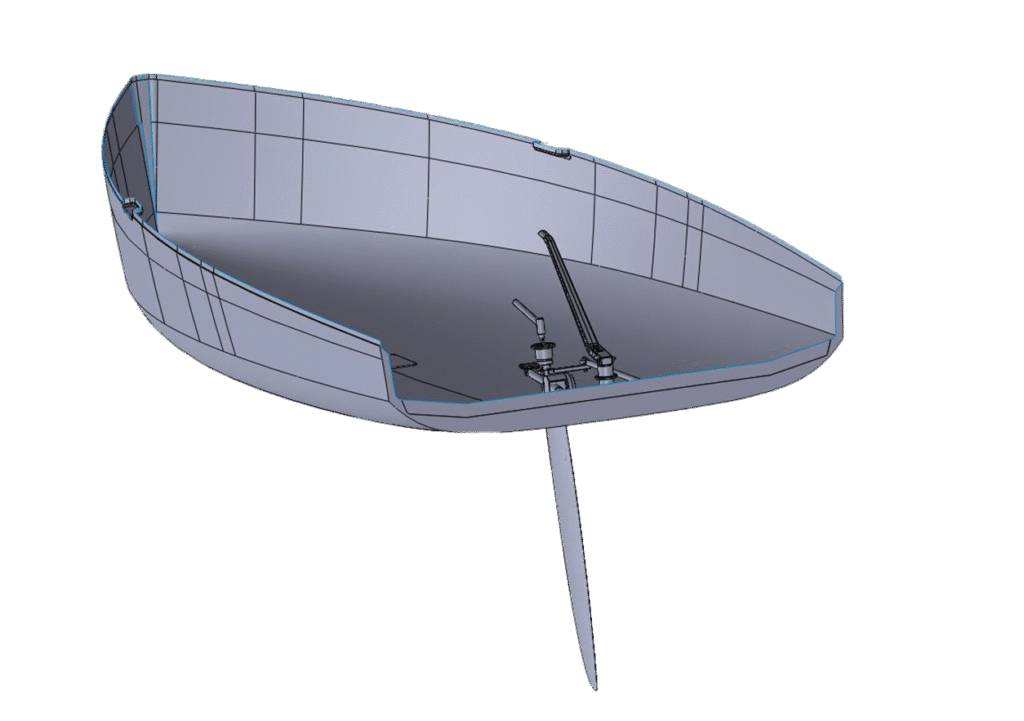

The fix’n place™ kits consist of pre-cut 3D|CORE™ foam cores and corresponding fabric and weave cut-outs. Self-centering reinforcement structures made from Cross|CORE™ for boats, aircraft, and vehicles complement these kits. We are also happy to offer mold making services.

With our essential technical knowledge, software, and hardware, we’ll guide you from prototype to series production.

Quick-Build Kits Directly from Your Drawing

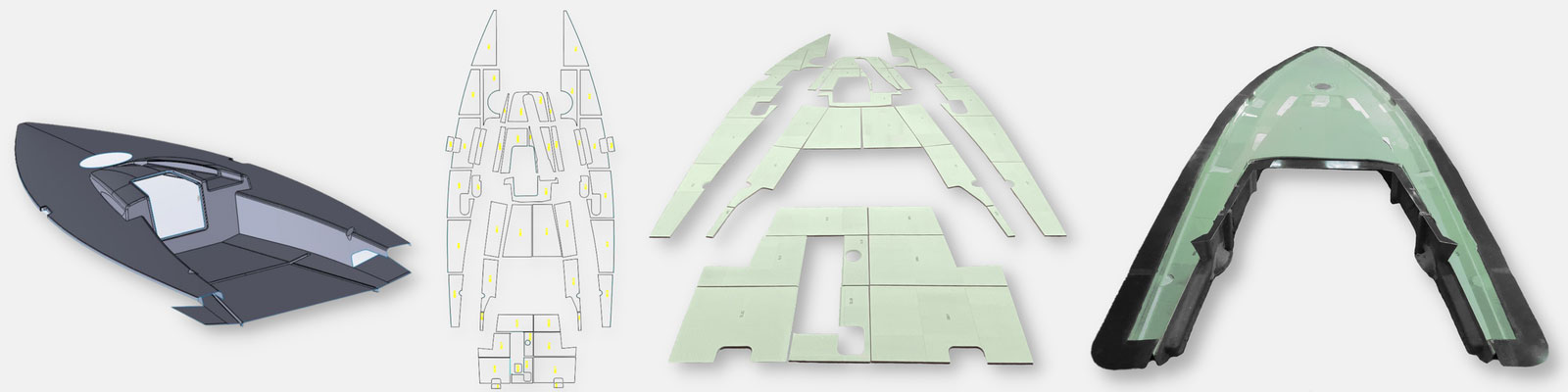

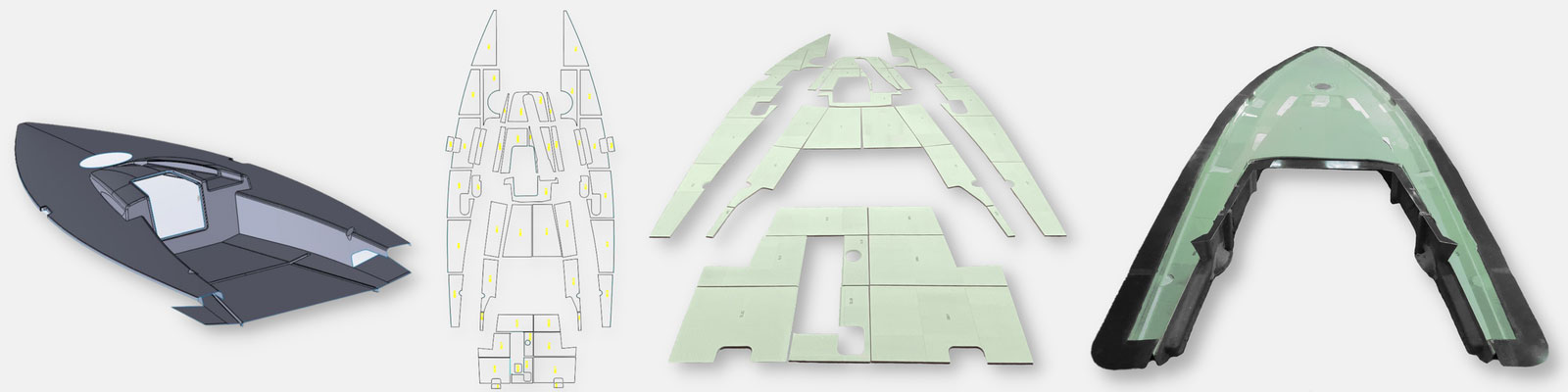

From digital design to finished cut-out: Our fix’n place™ quick-build kits are created based on your CAD data. The precisely fitting foam and fabric cut-outs are nested, labeled, and packed ready for assembly – including a placement plan for your mold.

What’s the Process?

3D Drawing as STL, OBJ, STEP, IGES, DWG, DXF, 3MF, and AMF files

- Please include the desired thickness and core properties. If you only have a sketch instead of a file, we’re happy to help. Absolute confidentiality is always the basis of our work.

- Drawing Review

- We’ll optimize your laminate plan with the 3D|CORE-Calculator if necessary – this almost always results in weight and material savings.

Determination of:

- Number of cut parts and components

- Foam type

- Costs

- Final weight

- Delivery rhythm, delivery quantity, and packaging

- Duration of the manufacturing process

Flattening Process

- Flattening Process (from 3D model to 2D model as the basis for cutting)

- Calculations

- Verification of the geometry of the cuts

- Optimization for effective material utilization (Nesting)

- Generation of cutting files

- Generation of a numbered placement plan for easy application

- Production of the Required 3D|CORE™ Material

- Production of a fix’n place™ Kit Prototype

- We produce a fix’n place™ kit prototype to minimize corrections on subsequent kits.

After Prototype Approval and Any Necessary Corrections:

- Production of the required 3D|CORE™ material

- Series production of fix’n place™ kits, consisting of 3D|CORE™ foam cores, textiles, and reinforcement structures.

Optimized Packaging for Especially Sustainable and Secure Transport

fix’n place™ PRODUCTION KITS

fix’n place ™ production kits accelerate your production process.*