QUALITY & ENVIRONMENT

Our entire company is geared to the development and manufacture of sustainable products and solutions of the highest possible quality. Our products are produced by ourselves.Through a stable supply chain, we ensure the consistent quality of the mechanical properties. We pay attention to high-quality and sustainable raw materials from proven suppliers and of undoubted origin.

With the help of low-emission and low-waste production processes as well as the economical use of resources, we actively take care of environmental protection. In addition, all our products are manufactured, stored and transported in accordance with technical standards and according to our customers’ specifications. The entire team is personally committed to quality, occupational safety and environmental objectives.

Our goal: satisfied and enthusiastic customers and partners.

We have a large network with long-standing suppliers and partners who share our quality and environmental concerns. We perform quality controls on our incoming goods, during production and before packaging. Most of our processes in production are automated, but some work steps are deliberately done by hand. This interaction is our way to perfection.

We keep our hierarchies flat and train our team continuously to stay flexible and dynamic.

Competent, personal and individual: we will find the optimal solution for you.

Our business processes are certified to DIN EN ISO 9001: 2015 and DIN EN ISO 14001: 2015.

SUSTAINABILITY CONCEPT

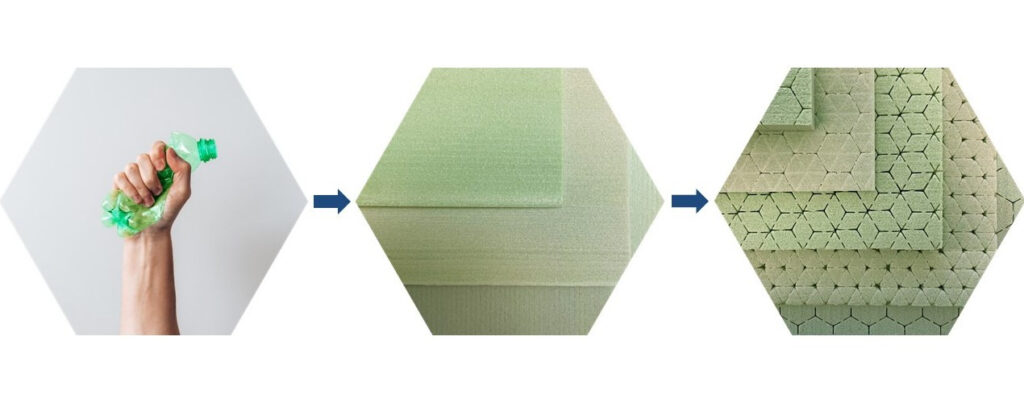

Our solution for a green future includes minimizing weight and maximizing component quality. We pay special attention to material and energy consumption in production, as well as the use of sustainable composite materials. Therefore, we offer 100% recycled and recyclable core material with excellent technical properties and avoid substances that are harmful to the environment and people.

In addition, our 3D|CORETM high-speed assembly kits reduce waste and guarantee optimal material consumption. With our in-house rapid prototyping, the possibility to produce small series and our optimized 3D|CORETM high-speed assembly kits, we avoid unnecessary transport and thus reduce your and our CO2 footprint.

Thanks to our wide-ranging know-how, as well as on the basis of our comprehensive composites database and your wishes, we compare your previous laminate plan, your currently used material, the process, as well as the cycle times. In doing so, we determine a possible degree of optimization, which shows all possible savings or improvements. This degree of optimization serves as a basis for your decision and as an indication for your calculations.

Potential savings:

- Weight: final component

- Material: resin, fibres, auxiliary materials

- Costs: process, material, labour