Technology

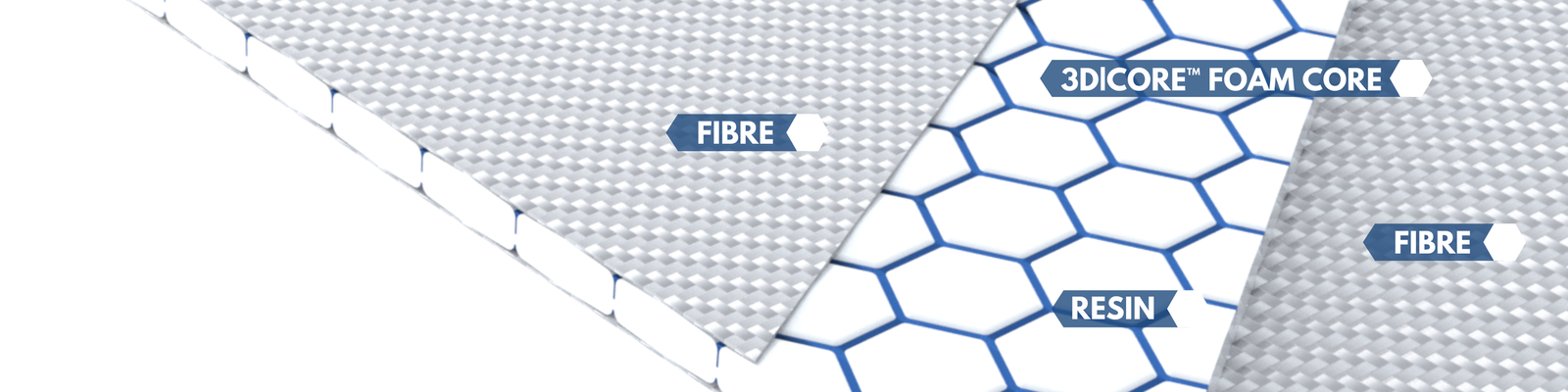

3D|CORE™ is a patented honeycomb structure that is inserted into a closed-cell PET or XPS foam core. Between the individual honeycomb foam bodies are cavities that are filled with a matrix of synthetic resin and support the filling process as an integrated flow aid. Once the matrix has cured, the foam core retains its shape and develops excellent technical properties.

Integrated Filling and Venting System

-

Integrated flow aid supporting the filling process with a liquid matrix (no additional flow aid required)

-

Increased process speed and reliability (optimal resin filling and wetting of the face sheets ensure a uniformly filled component)

Gives technical rigid foam cores maximum flexibility

-

Three-dimensional formability for the production of convex and concave components

-

Easy handling without pressure and heat

-

No additional processing steps required (no intermediate vacuum needed, as 3D|CORE™ foam cores adapt to the mold)

-

Increased drapeability (adjustment to complex shapes and contours)

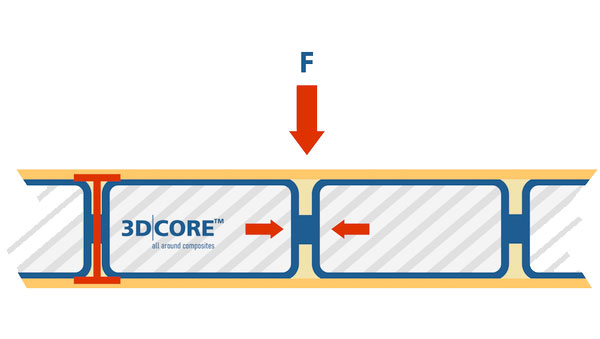

I-beam structure enables excellent mechanical properties

-

Improved shear and compressive performance compared to standard foam cores (800% higher compression modulus, 300% higher shear modulus)

-

Increased strength and stiffness compared to standard foam cores (500% higher flexural strength)

-

Optimal performance-to-weight ratio

-

Optimal absorption and transfer of forces (in-plane compressive loading significantly better than with conventional systems)

-

Reinforced 3D|CORE™ high-performance foam cores replace monolithic structures and other core materials in molds and final components