Cross|CORE™ Construction panels

Cross|CORE™ Construction Panels consist of a 3D|CORE™ foam core filled with an epoxy resin system to guarantee excellent strength, low weight, and long-term dimensional stability. The outer layers, made from fibers (including GRP, CFRP, Aramid) or HPL, can then be coated and printed in a variety of ways. The construction panels can be customized to your specifications regarding core thickness, outer layer, and fire protection class. You’ll receive an ultralight, ready-to-install composite component, which can also be delivered with inserts if desired.

To completely take over your production process, we deliver Cross|CORE™ Construction Panels not just as sheet material according to your drawing, but also as millimeter-precise cuts, including edge finishing according to your plan. Alternatively, our panels can also be post-processed with common woodworking machines.

Advantages in the Production Process:

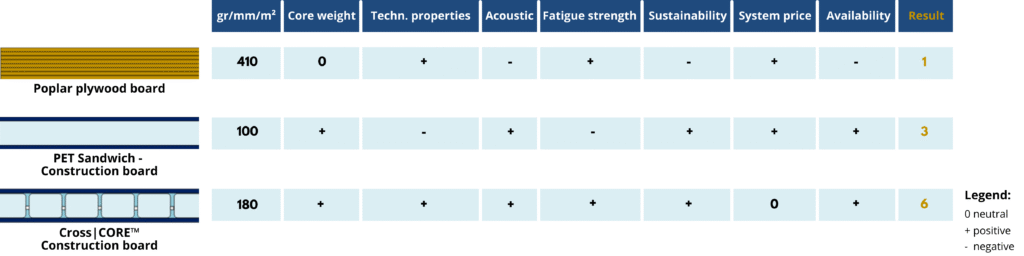

Thanks to the unique 3D|CORE™ structure, Cross|CORE™ Construction Panels offer significantly better properties than other foam core composite panels or wood. For example, they are characterized by excellent weather resistance, high tolerance accuracy, good acoustic properties, excellent strength, and high chemical resistance.

Comparison to Other Panel Systems:

Cross|CORE™ Construction Panels

Cross|CORE™ Construction Panels are also available as Cross|CORE™ GR with a recycled foam core.