ENGINEERING

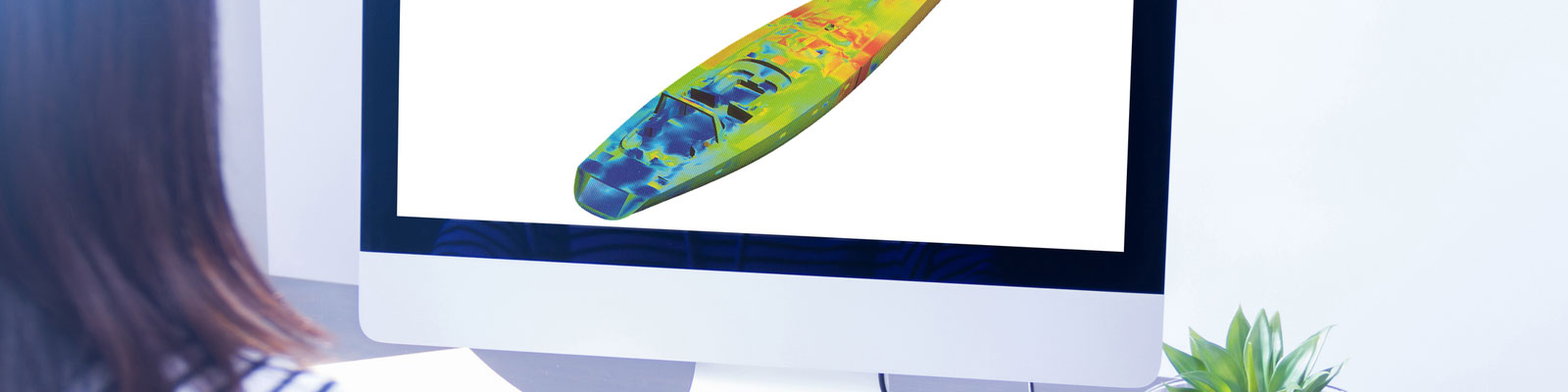

You want to improve an existing product (re-design) or have already put an idea on paper?

Our engineering team supports you from the very beginning of your idea, through the entire production chain to your final composite component. To enable an optimal design of your components, we analyze your planned lay-up, the product design, as well as your requirements and wishes.

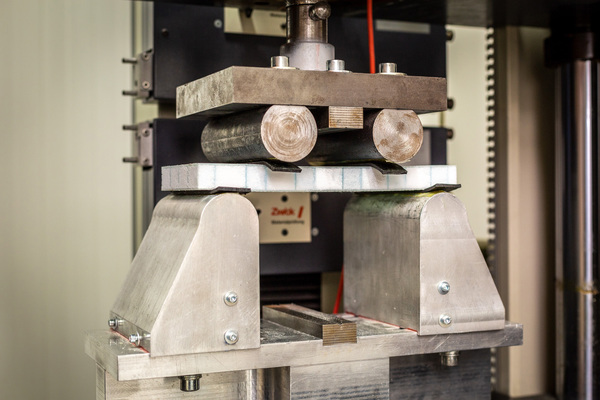

Determination and testing of the technical properties

Our specially developed 3D|Calculator calculates the technical properties of the composite component and simulates load cases to improve future performance. These include the three- and four-point bending test, as well as the cantilever beam to determine the bending moment. To validate our calculations, prototypes are produced in our technical centre, which then undergo extensive testing in our certified test laboratory.

Material savings

We pay special attention to the subsequent material and energy consumption in production, as well as to the use of sustainable composite materials. With the help of an efficiency calculation, we can provide you with a preliminary estimate of the possible savings and improvements. To ensure a fast time-to-market and an optimal material consumption of the 3D|CORETM foam cores and surface layers, we create cutting data which can be used to produce assembly kits for prototypes or serial components. It also allows you to speed up the production process and additionally minimizes your waste and shipping costs.

Your benefits

With the help of our optimized lightweight construction technology, we actively contribute to you being able to produce sustainable and cost-effective composite components faster than your competitors. You save time in product development, receive a lightweight component and the consumption of additional consumables is drastically reduced. In addition, we support you in the integration of our lightweight technology into your production.

Based on our extensive and long-standing know-how, we offer additional training and support you, among other things, in the certification of fire protection certificates.

SANDWICH OPTIMIZATION

By comparing possible lay-up combinations (topology) in terms of their technical properties, we can further optimize your planned laminate plan. We will find the balance between weight and performance for you. Thanks to our continuous material research, we have access to an extensive database consisting of empirically determined characteristic values of different composite materials.

Selection of the ideal composite materials

Our development engineers are always actively involved in new material decisions in particular. In order to always be able to make customer-oriented decisions in the area of material and raw material selection, we work exclusively with globally recognized manufacturers.

Our 3D|CORE™ PET foams, available in FR (fire retardant), GR (recycled) and XPS, always form the core of our solutions. To reduce your procurement expenses for additional composite materials, we supply fibers, resins, fillers, additives, coatings and consumables tailored to your application.

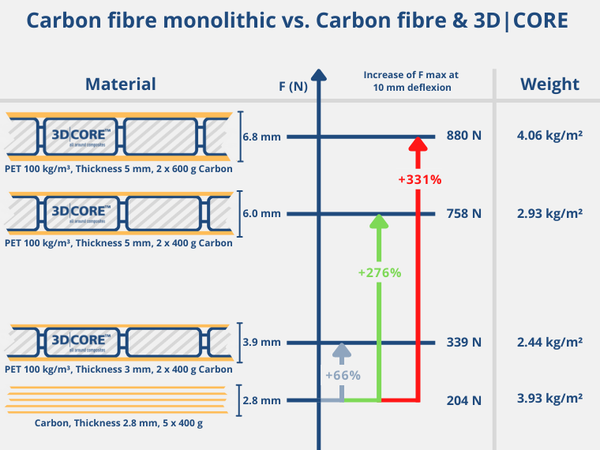

3D|CORE™ fibre composite construction vs. monolithic structure

Wherever lightweight construction is desired, a sandwich structure is required. We optimize existing sandwich structures and also convert monolithic components into sandwich structures. Our 3D|CORETM structure enables the saving of expensive fibre layers. The technical properties of the sandwich strcuture are improved immensely and this with a decreasing component weight.

The use of 3D|CORETM enables the reduction of fibre layers. This saves weight and improves the technical properties at the same time.

With 3D|CORETM you have the possibility to replace the initial and more expensive design with a more economical combination.

TAKE LESS – GET MORE

EFFICIENCY CALCULATION

Thanks to our wide-ranging know-how, as well as on the basis of our comprehensive composites database and your wishes, we compare your previous laminate plan, your currently used material, the process, as well as the cycle times. In doing so, we determine a possible degree of optimization, which shows all possible savings or improvements. This degree of optimization serves as a basis for your decision and as an indication for your calculations.

Potential savings:

- Weight: final component

- Material: resin, fibres, auxiliary materials

- Costs: process, material, labour